| MAG TILE Specifications | ||

| Construction | 1/12″ Gauge, 3/4/6 mm High-Low Tip Sheared Loop Pile | |

| Yarn Composition | 100% Solution Dyed Olefin | |

| Tufted Pile Weight | Ca. 712 g/m² (21 oz/yd²) (+/- 10%) | |

| Total Weight | Ca. 3446 g/m² (102 oz/yd²) | |

| Pile Height | Ca. 3 mm / 5 mm | |

| Total Height | Ca. 8 mm | |

| Secondary Backing | ECO Back – “PVC Free” | |

| Plank Size | 25 cm x 100 cm | |

| Packing | 20 pcs per box (5 m²) | |

| Performance | (as tested by ITTS Inc. USA) | |

| Stain Resistance | 10 (AATCC-175-2003) | |

| Static Control | Pass – Max. 4 kV (AATCC-134-1996) | |

| Tuft Bind | Pass – 10.3 lbs (ASTM-D-1335) | |

| Dimensional Stability | Pass – Max. 0.1% change (AACHEN) | |

| Pass – No VOC Detected (ASTM-D5116-10) | ||

| ΔL: 26 dB (ISO 10140) | ||

| αw 0.20 (ISO 354) | ||

| Hz 125 250 500 1000 2000 4000 | ||

| αs 0.01 0.03 0.08 0.28 0.35 0.43 | ||

| Flammability | ||

| – Pill Test | Pass – 8 (ASTM-D-2859-96) | |

| – Smoke Density | Pass – Max. 385 (ASTM-E-662-06) | |

| Colourfastness | ||

| – to light | Excellent – 5 (AATCC-16E) | |

| – to wet & dry crocking | Excellent – 5 (AATCC-165) | |

| – to ozone | Excellent – 5 (AATCC-129) | |

| Suitability | ||

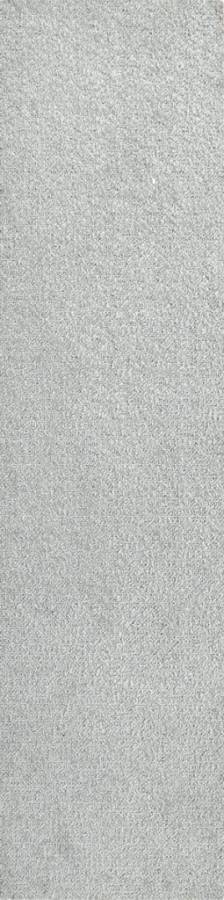

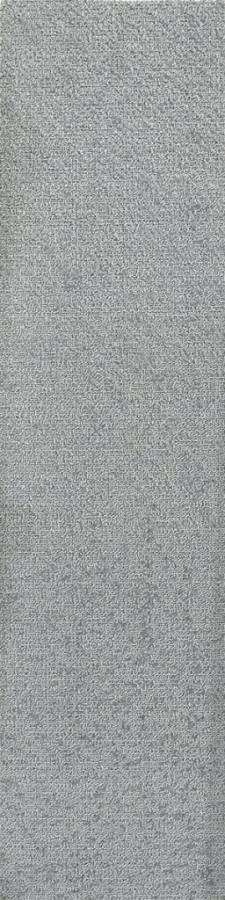

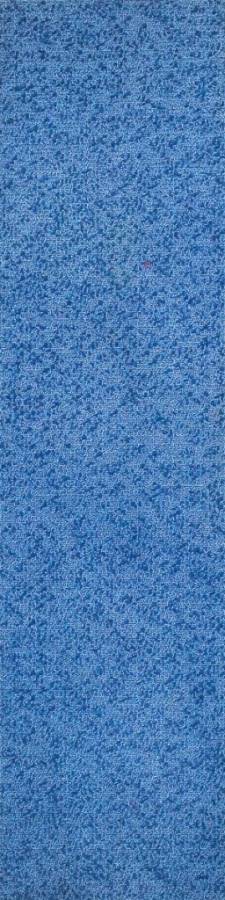

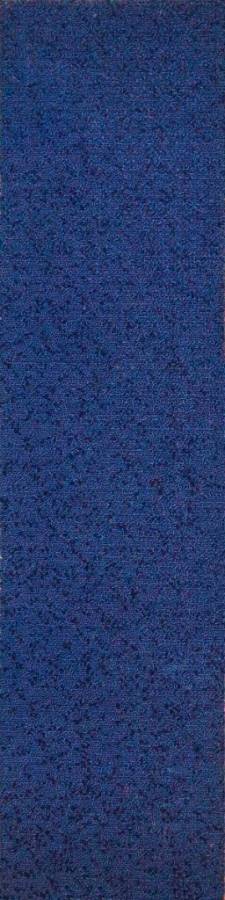

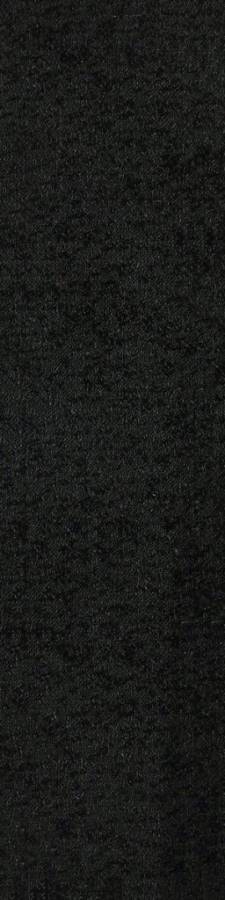

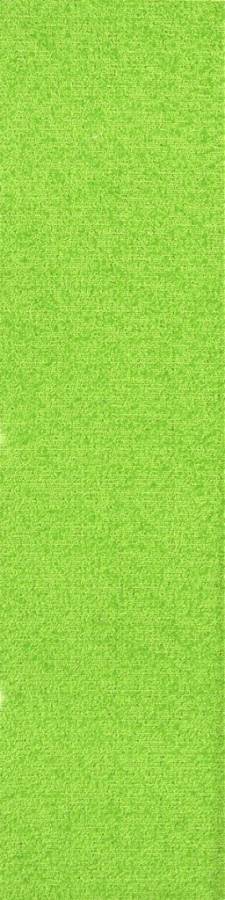

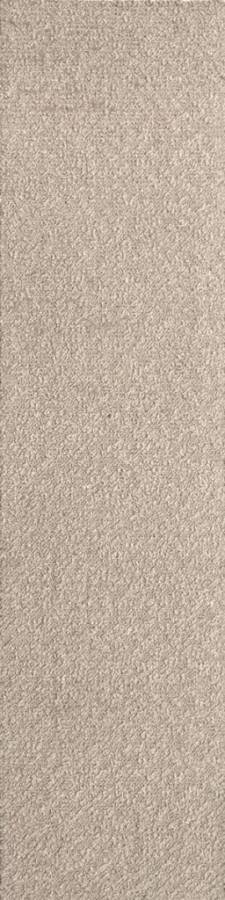

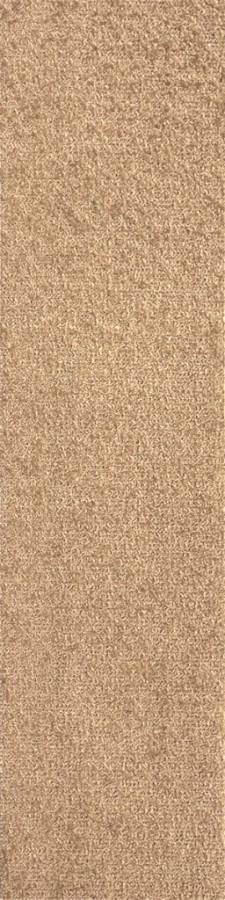

| Magical Tiles is an extremely affordable yet strong and durable carpet tile that fully meets the needs of today’s competitive office environment.

Due to the cut & loop texture and the solid colourations of Magical Tiles, the edge lines may be visible if planks of the same colour are joined next to each other. The visible edge lines are an inherent characteristic of the plank and not a defect, just as one can also see the edge lines when joining wood planks or PVC planks. If the visual effect of the edge lines is required to be minimised, we recommend installing planks of different and contrasting colours next to each other, as can be seen in our illustrations. |

||

| Ideal for Medium Commercial Use. | ||

| The subfloor should be dry, smooth, flat, dust-free and resistant to compression and load-bearing. Where seaming is necessary, a seam sealant must be used for all such installations. Due to dye lot variations, actual color may vary slightly from the samples. Chair pads are recommended to prevent premature wear of carpet. | ||

| Environment | ||

| The design and production of MAGTile conforms to the ISO 14001:2004 Environmental Management System and complies with environmental regulations.

As a responsible manufacturer and to minimize our carbon footprint, a majority of our excess production materials are recycled in-house resulting in a minimum of 10% recycled content in our tile backing. MAG Tile does not contain any PVC in its manufactured materials and packaging. MAG Tile is an environmentally friendly “green” carpet. |

||

|